As the conversation around sustainability continues to intensify, industries worldwide are being called upon to reduce waste and minimize their environmental impact. The construction industry, known for its significant contribution to global waste and energy consumption, is no exception. However, an innovative solution is emerging in the form of prefab wall panels. These components are playing a critical role in reducing construction waste and promoting sustainability in the industry.

The Problem of Construction Waste

The scale of waste generated by the construction industry is staggering. From offcuts and packaging to damaged materials and end-of-life waste, construction and demolition activities contribute significantly to landfill volumes. Not only does this waste have serious environmental consequences, but it also represents a substantial economic loss, as the materials discarded could have been put to better use.

The Promise of Prefabrication

Prefabrication offers a way forward. Prefab wall panels are produced in a controlled factory setting, where materials can be managed and utilized more efficiently. This approach minimizes waste generated during the production process, as any leftover materials can be recycled within the factory, used in other projects, or sold to recycling firms.

Reduced Material Waste

Prefabrication’s precision and efficiency lead to substantial waste reduction on construction sites. Traditional construction methods, where components are cut and fitted on-site, inevitably produce a significant amount of waste. However, prefabricated wall panels are manufactured to exact specifications, meaning there is little to no waste generated on-site during their installation.

Lower Energy Consumption

The production of construction materials and the construction process itself are energy-intensive. Prefabrication, with its centralized production and streamlined processes, can significantly reduce energy use.

Since prefabricated wall panels are constructed off-site and delivered ready for installation, the need for multiple deliveries of raw materials is eliminated. This reduces the carbon emissions associated with transportation. Moreover, because the panels are ready to install upon delivery, the amount of time and energy spent on site is also minimized.

Minimized Site Disturbance

Traditional construction methods can have a significant impact on the surrounding environment, from noise and air pollution to the disturbance of local ecosystems. Prefabricated wall panels, on the other hand, can help minimize these impacts.

With fewer materials and workers needed on site, site disturbance is significantly reduced. This not only minimizes the noise and disruption to the local community but also reduces the project’s overall environmental footprint.

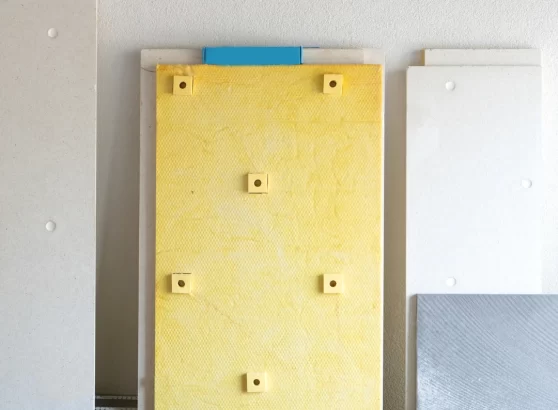

The Use of Sustainable Materials

Many manufacturers of prefabricated wall panels are also making a conscious effort to use more sustainable materials. Some are incorporating recycled materials into their panels, while others are using sustainably sourced timber. This commitment to sustainability enhances the environmental benefits of prefabricated wall panels.

Conclusion

The construction industry has a critical role to play in the global push towards sustainability. Prefabricated wall panels represent a promising solution, offering a practical and effective way to reduce construction waste, minimize energy use, and lessen environmental impact.

The growing recognition of these benefits is leading to an increased adoption of prefabricated wall panels in construction projects of all sizes. As this trend continues, it’s clear that these innovative components will play an increasingly important role in shaping a more sustainable future for the construction industry.

Contact RGZ Cambridge today for all your prefabricated wall panel needs: We are industry leaders in Commercial and Residential projects. Call us today: 613-695-5544 or reach us via this page.